Prime Shrink Wrap Protection

Prime Shrink Wrap Protection

We provide Shrink Wrap Containment services across New Zealand for the building, construction, and industrial sectors. Our qualified and trained installers, with expertise in height safety and advanced site protocols, ensure proper installation, repairs, and removal of shrink wrap for a variety of applications, including construction renovations, hazardous material containment, marine protection, and more. We also offer post-removal plastic collection for recycling, contributing to sustainable waste management. Shrink wrap solutions are versatile, catering to modular buildings, emergency structures, transport storage, and temporary enclosures, all providing weatherproof, secure protection.

Applications

Construction Scaffolding

Shrink wraps provide a weatherproof enclosure for scaffolding, shielding workers and structures from rain, wind, and debris. This ensures uninterrupted progress on projects while maintaining safety and cleanliness.

Heritage Protection

Delicate heritage structures are safeguarded with shrink wraps, offering a sealed barrier against environmental elements like dust, moisture, and pollutants. This preserves intricate details during restoration or renovation.

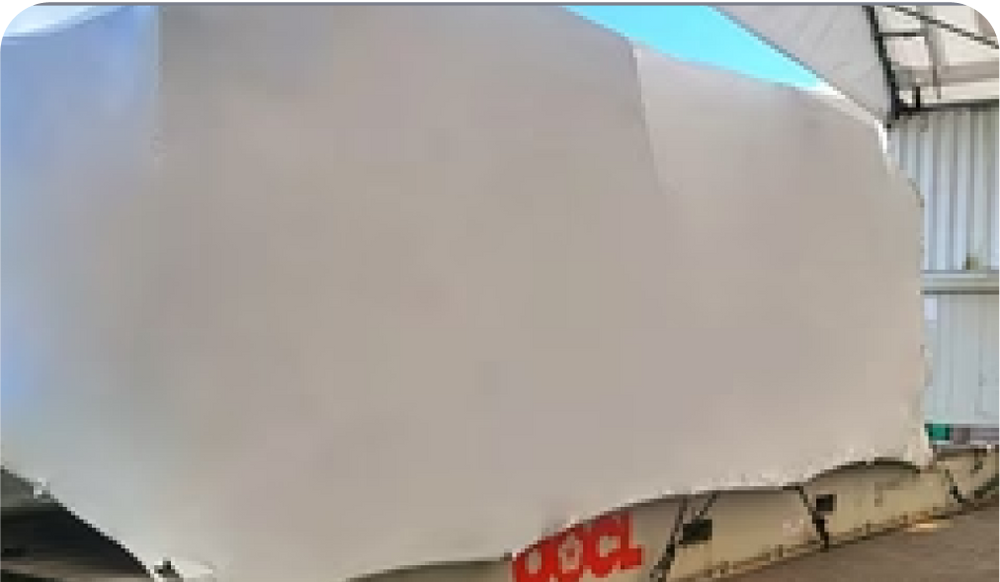

Marine

Shrink wraps protect boats, yachts, and marine equipment from UV rays, saltwater corrosion, and harsh weather during transportation or off-season storage, ensuring longevity.

Industrial Containment

In industrial settings, shrink wraps create a sealed environment containing dust, fumes, or hazardous materials during maintenance or repair, meeting safety standards.

Logistics Cargo

Shrink wraps secure goods on pallets, preventing movement, moisture damage, and tampering during transit, ensuring safe delivery to their destination.

Storage & Warehousing

Provides a durable and airtight covering for stored items, protecting them from dust, dirt, and environmental factors in long-term or temporary warehousing.

Modular Building

Shrink wraps safeguard prefabricated building components during transport and on-site assembly, ensuring they remain clean and undamaged until installation.

Why Use Shrink Wraps?

Why Prime Solutions?

Struggling to install? We’ll take care of it!

If you’re having a hard time installing products, don’t stress out! Applying any item can be a really exhausting task. However, when done right and with the help of experts, it’s just a piece of cake!

Did you know we don’t just provide Shrink Wrap supplies, but also offer installation services? You read that right! Prime Solutions has a team of experts who leverage their years of field experience to provide quick and efficient installation solutions.

So, what are you waiting for? Give us a ring and we’ll be there in no time!

Reach Out to Us

Contact us if you need support

Need some help?

Speak to our experts

Why not start a live chat with one of our team members now? We can assist Monday to Friday between 8:00am and 4:30pm.

Call Us NowFrequently Asked Questions

Shrink wrap is a plastic film that shrinks tightly around an object when heat is applied. It creates a snug, protective barrier that helps keep your items safe from dust, moisture, and damage!

Shrink wrap is super versatile! It’s commonly used for protecting construction materials, packaging equipment, securing pallets, and even covering furniture during moves. It’s a solid solution for keeping things clean and safe.

Yes! While traditional shrink wrap is made from plastic, many manufacturers now offer eco-friendly options that are recyclable. Just be sure to check for labels that indicate sustainability!

Applying shrink wrap is easy! Simply cut a piece to size, wrap it around your item, and use a heat gun to shrink it down. Just remember to keep the heat moving to avoid burning the wrap. It’s like giving your items a warm hug!

Shrink wrap is typically designed for one-time use, but if you handle it carefully when removing it, you might be able to reuse it for smaller items. Just keep in mind that it may not adhere as well the second time around.

Removing shrink wrap is a breeze! Just grab a pair of scissors or a utility knife, and carefully cut along the seam. Make sure to keep your fingers clear of the blade, and you’ll have your items free in no time!